Experience in choosing construction materials for your project

Building a house is an extremely important task in a person’s entire life, so anyone in the construction would like to have a durable, comfortable and affordable house. To ensure the house is as you want, the selection of building materials is the first factor determining the quality of the building.

So how to choose good materials, quality assurance, safety and prices are consistent with economic conditions. With practical knowledge, we will share with you the following experiences when choosing construction materials as follows:

1. Construction bricks

Brick is an indispensable material in the construction process, there are many types of bricks including unburnt bricks, terracotta bricks … We can check the building bricks through visual observation. Often good bricks will have a standard shape with sharp edges, the colors of the bricks are similar, the same. For a more objective assessment, you can apply the following methods:- Drop the bricks from a height of 1m, if broken bricks, this type of quality is not good. Should choose the bricks which is not shattered after being dropped.- Smash 2 bricks together, if the sound is definitive, sharp, and clear, this is a good quality brick.- Soak bricks in water for 24 hours. Then check the weight of the bricks before and after immersion. If the weight of bricks is 15% heavier, this type of bricks should not be used. For example, a brick weighing 2kg, after being soaked can not weigh more than 2.3 kg, it will ensure the requirements of construction.

2. Cement

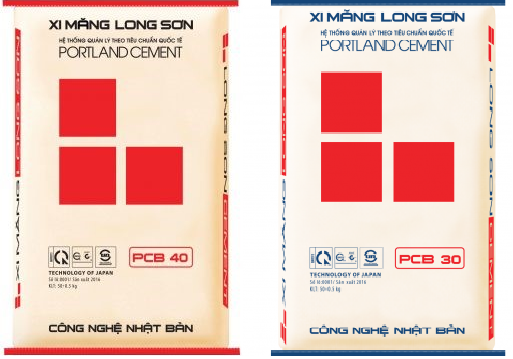

Cement is an irreplaceable binder of concrete and mortar, when meeting with water cement helps sand, gravel, stone … connect to form a unified block.During the general development of the cement industry today, the cement is circulating in the market supplied from many different sources. This is both an advantage and advantage, but also causes many difficulties for consumers when there are too many choices.You can preliminary check the quality of cement in the site by the following ways:- Packing date: Manufacturing date will be visible on the bag. It is important that the strength of cement will decrease with age.- Brush: take a little cement and rub with 2 fingers. If quality cement, it will be smooth.- Insert by hand: you have a cool feeling when putting your hand in the cement bag, which means that the quality of cement is not out of date. It has no Hudratification reaction in the cement bag.- Floating test: take some cement into a bucket of water. If it sinks, it is quality concrete.- Odor test: if you can smell the soil, it proves that the cement contains too much clay and mud.- Presence of lumps: there should be no lumps in cement bags.To more accurately assess the quality of a cement, you can ask the sales or manufacturer to provide you with a specific quality certificate of the cement shipment you are interested in. You can compare among the quality certificate of cement companies present or at the same time. You can find out the quality of Long Son Cement products PCB30 and PCB40 here.

3. Construction stone

Construction stone usually includes types: 1 × 2, 3 × 4, 4 × 6…. As a material used to increase the load capacity of concrete. Aggregate stone when put into use should note some of the following requirements:- Use of impurities, clean, less impurities to limit the work of workers.- Eliminate impurities in construction stone by sieving through wire mesh or washing with water.

4. Select construction iron and steel

Steel plays a key role in every building, capable of supporting hard and fragile concrete layers. Depending on the use of each type of construction, you need to choose the appropriate iron and steel respectively. Here are some experiences of choosing iron and steel in construction:- Choosing iron and steel to build houses needs to choose a reputable steel brand in the market- Choosing steel to build houses – Need to determine the quantity and reasonable cost of construction- Requirements for transporting and preserving steel in construction- You can consult the construction engineer to give you the most suitable iron and steel for each type of structure.

5. Construction sand

Construction sand includes: construction sand, concrete sand, sand leveling, etc. Some experience when selecting sand for construction:- Choose the right sand for the location to build:

– medium grain sand to build walls and bowl, fine-grained sand used to level the foundation, large grain sand to make concrete.

– You can get a rough idea of the quality of the sand by taking a handful of sand. That way the dirt and mud will stick to your hands. This will determine whether the sand is clean or dirty sand. You should choose clean sand to facilitate the use.

– If the content of mud and dirt exceeds 3% of the total amount of sand, it is necessary to clean before use. It can be tested by dropping sand into a glass jar, the sand will settle down, dirt will float to the top, you will check the amount of dirt and sand in the building.

– Check whether the sand is alum or salty before buying to ensure the quality of construction.

6. Water

It seems that it does not affect much, but the water source has a small impact on the quality of mortar and concrete. You should use clean water, absolutely do not use sea water, alum water, pond water, brackish water, oily water, grease to build houses. The right amount of water in accordance with the cement ratio will help solid construction.